SERIES

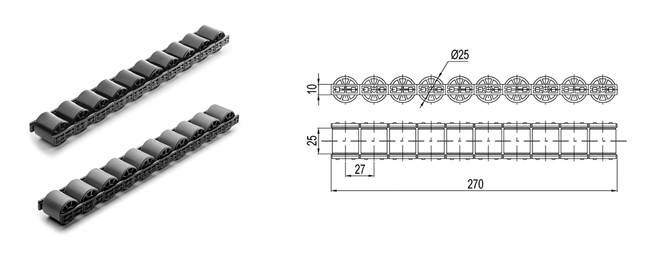

RLT-U

Roller elements

Acetal resin based (POM) technopolymer roller holder, black colour.

- RLT-U-PA: polyamide based (PA) technopolymer rollers, black colour.

- RLT-U-TPU: thermoplastic (TPU) polyurethane rollers, hardness 92 Shore A, grey colour.

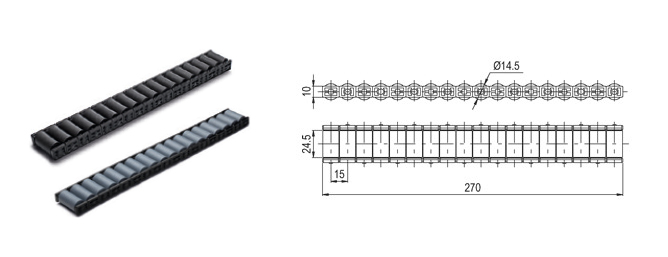

RLT-U15

Roller elements

- Rollers: polyamide based (PA) technopolymer, black colour

- Roller holder: acetal resin based (POM) technopolymer, black colour.

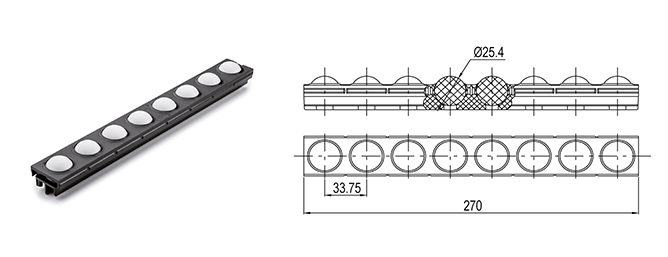

RLS-U

Ball elements

- Balls: acetal resin based (POM) technopolymer, white colour.

- Ball holder: polyamide based (PA) technopolymer, black colour.

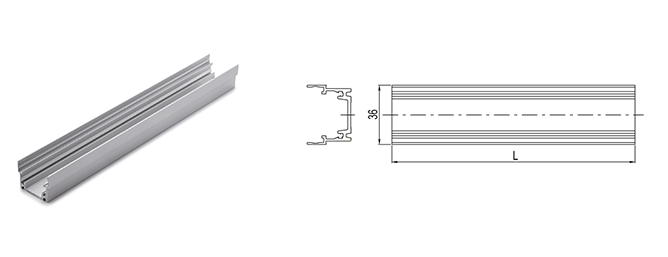

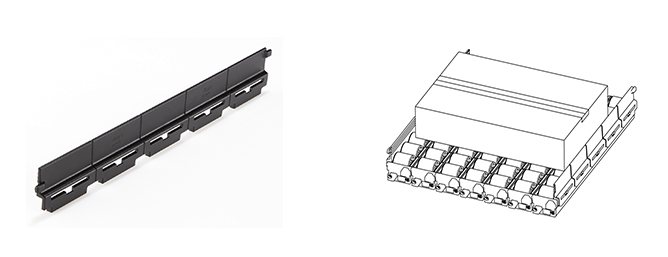

RLT-AL

Aluminium profiles

The profile can hold up to 11 RLT-U roller elements or RLS-U ball elements. The profile ensures a high resistance to bending under load, and the assembly of the roller tracks without the need for other supports.

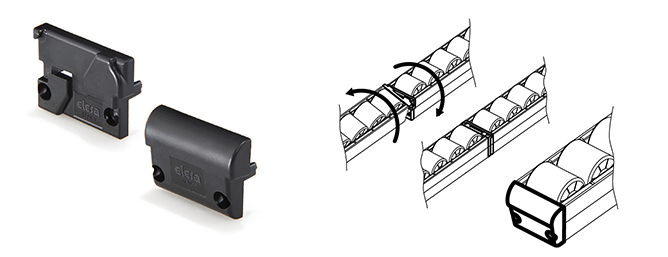

RLT-H

Headers

RLT-HJ header serves to bind tightly two rollers by engaging them. RLT-HE header is the end-element of roller tracks. In addition to being an aesthetic element, the headers represent a safety element for the operator's hands and the handled material.

RLT-CE

Containment edge

RLT-CE containment edge is used for the lateral containment of products handled on roller tracks. It is snap-in assembled on RLT-AL aluminum profiles without the need for screws or other fasteners. It can also be mounted to the roller track already fixed.

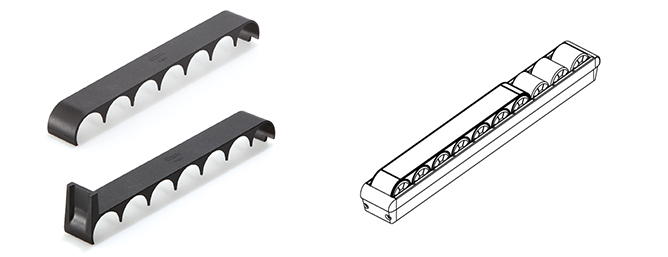

RLT-B

Brakes

RLT-B brakes allow to slow down and/or stop packages handled on roller tracks. The brakes are snap-in assembled on RLT-U roller elements without the need for screws or other fasteners.

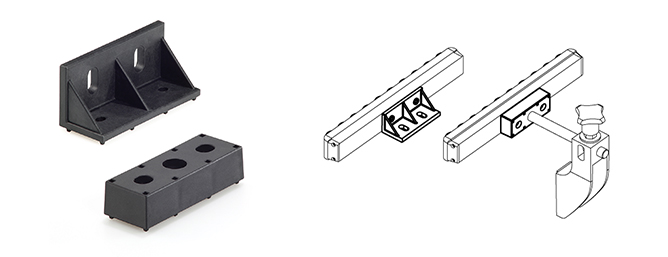

RLT-M

Bracket and support

The bracket and the support facilitate the mounting of roller tracks on machines and other supporting structures.

* Trademark application

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs