GUIDELINES FOR THE CORRECT APPLICATION OF PLASTIC HINGES

Materials of different type are used in accordance with the different structure and functionality of the hinges:

- High-resilience elastomer based technopolymer.

- Glass-fibre reinforced polyamide based or acetal based technopolymer.

- High-rigidity SUPER-technopolymer.

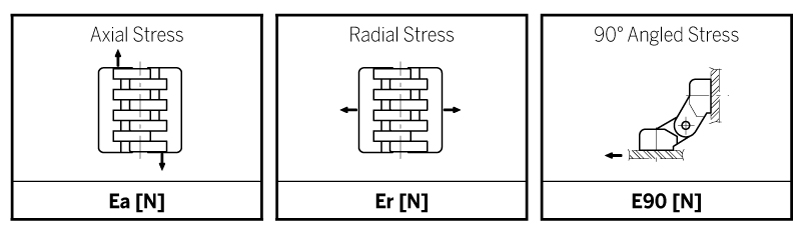

Resistance tests: two values are supplied for each product code:

- Maximum working load (Ea, Er, E90) is the value under which any elastic deformation that may occur is not permanent thus ensuring the hinge functionality.

- Load at breakage (Ra, Rr, R90) above which the plastic material can break.

For materials with high rigidity (SUPER-technopolymer) which are not significantly deformed even with loads very close to loads at breakage, only the max limit static load is given (Sa, Sr, S90). Therefore, the technical designer, when calculating the admissible load, will have to use a suitable factor according to the importance and the safety level of the specific situation.

All the values shown in the tables (Ea, Er, E90 and Sa, Sr, S90) are the result of tests for the corresponding stresses carried out in our laboratories under controlled temperature and humidity (23° C - 50% R.H.) under given conditions of use and for a limited period of time. When assessing the safety factor to apply, the technical designer shall take into consideration the actual conditions of use if they are different from the laboratory ones.

In order to help the technical designer to choose the right hinge and check its suitability to the specific application, we suggest asking for test samples and submitting the chosen product to tests in order to check its suitability.

The methods for calculating and interpreting the resistance values described in this catalogue have been updated in accordance with the latest improvements achieved.

Hinges CFN. and CFO. series: E90 stress is not applicable, due to their geometry and structure. CFS. hinges with built-in safety switch: being safety devices with specific properties, they require a specific argumentation which is illustrated in the product datasheet.

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs