1.1 Position indicators

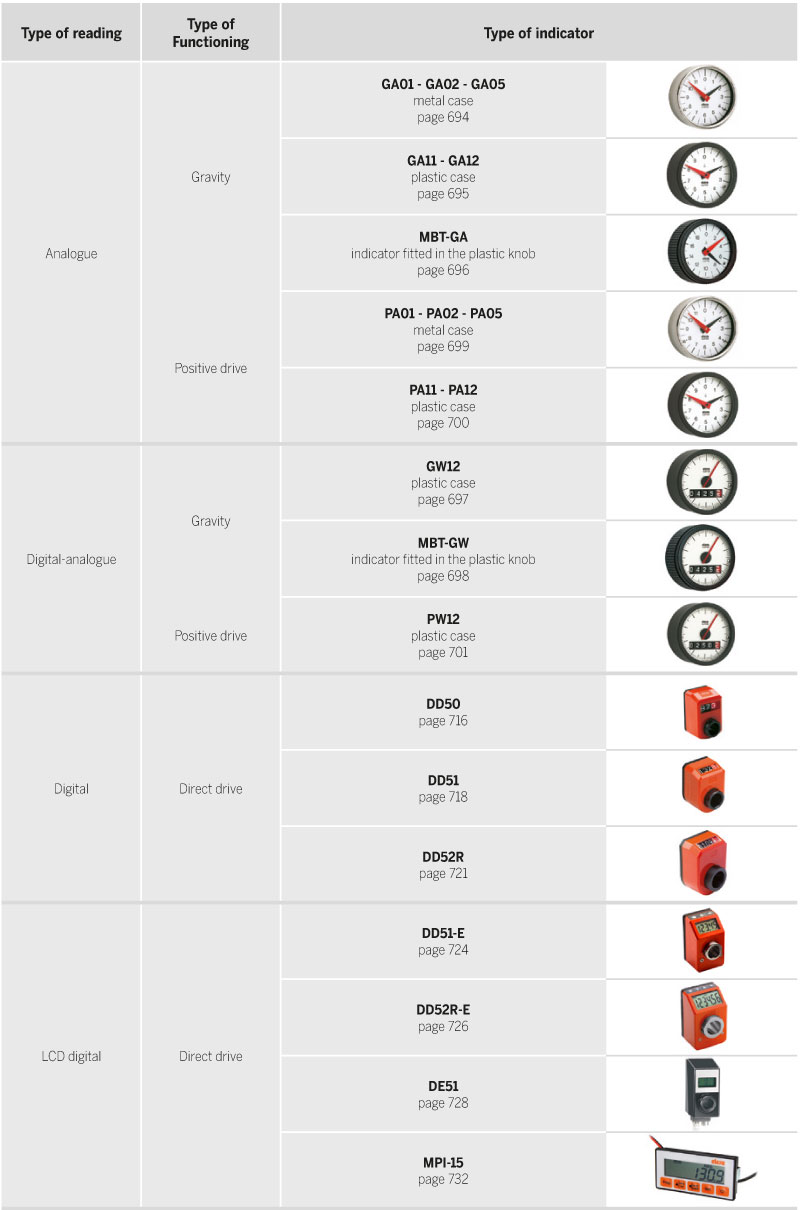

ELESA-CLAYTON position indicators can be classified according to the type of reading or movement.

The indicators are normally supplied separately from their relative handwheels/knobs, except for integral models, whose indicator is fitted in during the production.

Type of reading

Analogue: the reading is displayed by means of two rotating pointers over a graduated dial.

Digital-Analogue: the reading is directly displayed by means of a roller counter and a rotating pointer over a graduated dial.

Digital: the reading is directly displayed by means of a roller counter.

LCD Digital: the reading is directly displayed by means of a digital electronic display.

The analogue indicators are normally provided with a graduated dial and two pointers which indicate the number of turns and part of a turn made by the control spindle starting from an initial positionzero.

The indicators with digital-analogue, digital and LCD digital reading are provided with a roller counter or a display which indicates the linear displacement of the machine element connected to the

control spindle from the initial position zero.

Type of functioning

Gravity Movement: is used when the handwheel spindle is horizontal or max 60 inclined. The rotation of the handwheel with the indicator makes the pointers move while the dial, appropriately counterbalanced, is kept still by the gravity force.

Positive drive Movement: is used on spindles in any position. The rotation of the handwheel with the indicator makes the pointers move while the dial is kept still by an anchor pin fitted to the machine.

Direct drive Movement: is used on control spindles in any position, the indicator is directly mounted on the control spindle and is kept in position by means of a referring back pin.

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs