Requirements, design principles

DESIGN REQUIREMENTS FOR HYGIENIC DESIGN

Material

- Non-rusting Stainless Steels

- FDA and EU compliant plastics and elastomers

Surfaces

- Surfaces must be able to be cleaned

- Steps due to appliance configurations which are not aligned must be avoided

- Seals must be designed so that no gaps occur

- O-ring grooves must be hygienically designed

- Contact with the product to be manufactured must be ruled out

- Corners should preferably have a radius of 6 mm or more

Design / Geometry

The interior and exterior areas of all appliances, components or piping must be self-draining or be able to be drained and easy to clean.

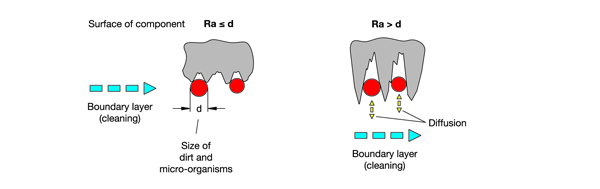

Surface properties and roughness

Easy to clean with Ra < 0.8 μm

DESIGN PRINCIPLES FOR HYGIENIC DESIGN

EHEDG

- European Hygienic Engineering & Design Group

- non-profit European consortium of machine and food manufacturers

- as well their suppliers, research institutes, universities and government health agencies

- approximately 45 guidelines

- examination of products and issue of certificates

3-A Sanitary Standard, Inc.

- non profit and independent association in the USA

- three interest groups:

- public and governmental health agencies, machine and food manufacturers

- over 70 Sanitary Standard

- examination of designs and processes, issue of certificates

LEGAL BASIS OF HYGIENIC DESIGN

EN 1672-2:2009 “Food machinery”

Machines must be able to be cleaned, i.e. they must be designed and constructed so that dirt can be removed with the recommended cleaning methods.

Machinery directive 2006/42/EC

Machines must be designed so that

materials can be easily and fully cleaned before each use and

no risk of infections or illness is created

DIN EN ISO 14519:2008-07

Hygiene requirements for the design of machines

DIN EN 1672:2009-07

Food machinery – General design principles – Part 2

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs