Close

Download

Load Capacity of Ball Lock Pins / Locking Pins

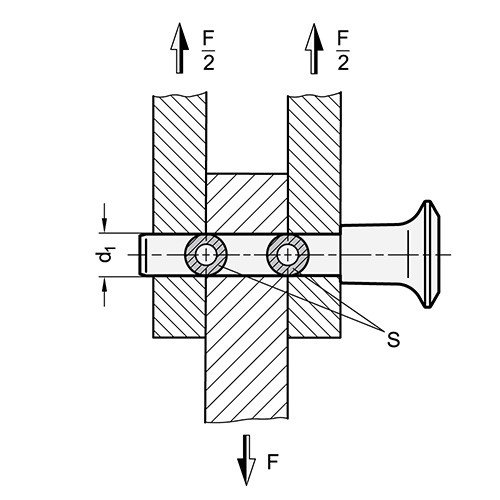

Double Sided Shearing Resistance

The load capacities specified in the table for the double sided shearing resistance (breaking strength) have been calculated or theoretically defined on the basis of DIN 50141.

At the same time, the endangered bolt cross-section S, according to a nearby sketch, was considered in two shear planes before breakage.

The details given on load rating are non-binding guide values without any liability. In general, they do not constitute a warranty of condition.

The user must determine whether the product is suitable for the intended purpose. Environmental factors can influence the specified values.

An appropriate safety factor must be taken into account in the design.

| Ball Lock Pins Load capacity F in kN ≈ Double sided shearing resistance acc. DIN 50141 (Breaking strength) | |||||

|---|---|---|---|---|---|

| d1 | GN 113.3 GN 113.7 GN 113.9 GN 113.11 | GN 113.4 GN 113.8 GN 113.10 GN 113.12 | GN 113.5 | GN 113.6 | GN 113.30 |

| Pin diameter | |||||

| 5 | 14 | 24 | 14 | 24 | - |

| 6 | 21 | 35 | 21 | 35 | 23 |

| 8 | 38 | 63 | 38 | 63 | 43 |

| 10 | 60 | 100 | 60 | 100 | 69 |

| 12 | 87 | 144 | 87 | 144 | - |

| 16 | 155 | 587 | 155 | 257 | - |

| 20 | 244 | 403 | - | - | - |

| 25 | 386 | 631 | - | - | - |

| Lock Pins Load capacity F in kN ≈ Double sided shearing resistance acc. DIN 50141 (Breaking strength) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| d1 | GN 114.2 GN 114.7 GN 114.11 | GN 114.3 GN 114.6 GN 114.8 GN 114.12 | GN 124.1 GN 124.2 | GN 124.3 | GN 214.2 | GN 214.3 GN 214.6 | GN 314 | GN 2342 | |

| Pin diameter | |||||||||

| 6 | 14 | 17 | 22 | - | 14 | 17 | - | - | |

| 8 | 28 | 35 | 40 | 40 | 28 | 35 | 30 | 32 | |

| 10 | 38 | 47 | 62 | 62 | 38 | 47 | 46 | 57 | |

| 12 | 61 | 75 | 90 | 90 | 61 | 75 | 74 | 80 | |

| 16 | 113 | 138 | - | - | 113 | 138 | 136 | 156 | |

| 20 | 187 | 228 | - | - | - | - | 227 | 247 | |

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs