Close

Download

TECHNICAL DATA AND GUIDELINES FOR THE CHOICE

Basic data required

- disturbing frequency: the frequency of the disturbing vibration produced by a on-duty machine. In general, it is obtained by the number of rotations of the engine [Hz=r.p.m./60];

- the load applied to every single vibration-damping element [N];

- the isolation degree required [%];

- the deflection value of the vibration-damping element under a given load [mm];

- the rigidity [N/mm], that is to say the load that applied to the vibration-damping element produces a deflection of 1.0 mm.

How to choose the vibration-damping element

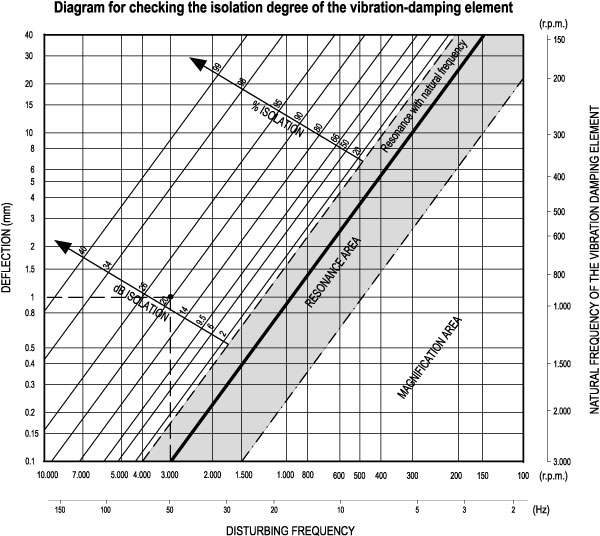

- with reference to the diagram for checking the isolation degree, intersect the disturbing frequency value with the isolation degree required (each isolation degree corresponds to a line in the diagram) and define the deflection [in mm];

- divide the load applied onto the vibration-damping element by the deflection value to obtain the required rigidity of the vibration-damping element;

- compare the rigidity obtained with the rigidity shown in the table and choose the vibration-damping element which presents the nearest value (lower) to the calculated one.

- the rigidity values reported in the table refer to the maximum load values.

- the designer must verify that the article chosen through this selection criterion is suitable for the application required, in any case. For this purpose on request for each article, non-linear graphs of the spread (according to the applied load) are available.

Example

Conditions of use:

- disturbing frequency= 50 Hz (3,000 r.p.m.);

- load applied on each vibration-damping element 120 N;

- 90% isolation required;

- diagram shows that with a 50 Hz disturbing frequency and an isolation degree of 90%, the deflection obtained is 1.0 mm;

- divide the load applied by the deflection obtained to define the rigidity required, which is 120/1.0 = 120 N/mm;

- compare the rigidity value obtained (120 N/mm) with the values reported in the table;

- the values reported in table, for type DVA.1, show that the vibration-damping element which should be used is DVA.1-25-20-M6-18-55.

-

Generals

-

1. Plastic materials

- 1.1 Mechanical strength

- 1.2 Thermal resistance

- 1.3 Strength and surface hardness

- 1.4 Resistance to chemical agents

- 1.5 Resistance to atmospheric agents and uv rays

- 1.6 Flame resistance

- 1.7 Electrical properties

- 1.8 Surface finish and cleanability

- 1.9 Compliance with international standards

- 1.10 Competence of Elesa+Ganter technical department

- 2. Metal materials

- 3. Other materials

- 4. Machining tolerances

- 5. Fixed handles

- 6. Assembly measures

- 7. Special executions

- 8. Colours

- 9. Test values

-

10. Technical tables

- 10.1 Conversion tables

- 10.2 DIN 79 Square holes and shafts

- 10.3 DIN 6885 Keyways

- 10.4 GN 110 and GN 110.1 Transversal holes

- 10.5 DIN 13 ISO Metric threads

- 10.6 DIN 228 Cylindrical GAS-BSP threads

- 10.7 DIN EN ISO 898-1 | DIN EN 20898-2 Strenght values

- 10.8 DIN ISO 286 ISO-Fundamental tolerances

- 10.9 IP Protection Classification

- 10.10.1 PFB | PRB Thread locking with jamming action Polyamide patch coating/ Polyamide complete coating

- 10.10.2 MVK Thread locking gluing Micro encapsulation precote 80 (red)

- 10.11 Stainless Steel characteristics

- 10.12 Surface treatments

- 10.13 Carbon steel, zinc alloys, aluminium, brass characteristics

- 10.14.1 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.2 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.14.3 Duroplast, elastomer, technopolymer and rubber characteristics

- 10.15 Load ratings U-Handles

- 10.16 Load ratings metal hinges

- 10.17 Strength of indexing plungers

- 10.18 Assembly sets GN 965 and GN 968

- 11. Vibration-damping elements

-

1. Plastic materials

- Hygienic design

- Operating Elements

- Clamping knobs

- Control elements

- Rotary controls

- Indexing elements

- Joints

- Transmission elements

- Levelling elements

- Hinges

- Latches

- Toggle, power and hook clamps

- Accessories for hydraulic systems

- Tube clamp connectors

- Castors and wheels

- Magnets

- Conveyor components

- Linear slides

- Vibration mounts

- Vacuum components

- Elastomer springs